A Scot in a kilt. Growing microgreens in Sweden.

Every Monday and Thursday, Graham sets off from his farm in Frillesås, Sweden with a truckload of freshly harvested microgreens grown in his indoor vertical farm. Originally from Scotland, Graham turns heads when supermarket shoppers realize the man arranging his produce on shelves is dressed in a kilt. Customers may wander over initially to ask where he’s from, but once they are drawn in, the outgoing farmer engages his audience about the health benefits of microgreens and earth-friendly farming techniques he employs at his company, Greeny Grow.

Microgreens packed with nutrients

Graham explains that customers are amazed to learn about the nutritional punch packed in these miniature vegetables. Says Graham, “They have more vitamins and minerals than the full-grown versions.” He reveals that peas in microgreen form have 7x more vitamin C than blueberries and all his produce which includes kale, mizuna, parsley and the rest, are loaded with antioxidants.

Graham believes that so many diseases that put a strain on our health care systems could be avoided if consumers made better food choices. “People just buy these ready-made meals and don’t take time to cook. It’s sad.” He plans to encourage more home cooking by providing simple recipes using QR codes. “You can easily make a quick, healthy meal just by cooking up some scrambled eggs and sprinkling a few broccoli microgreens on top.”

Graham believes that so many diseases that put a strain on our health care systems could be avoided if consumers made better food choices. “People just buy these ready-made meals and don’t take time to cook. It’s sad.” He plans to encourage more home cooking by providing simple recipes using QR codes. “You can easily make a quick, healthy meal just by cooking up some scrambled eggs and sprinkling a few broccoli microgreens on top.”

Graham always features a microgreen of the month to encourage people to try something new. Superfood status aside, microgreens will entice even picky eaters with their wonderful flavors. “Kids won’t eat their broccoli, but they really like broccoli microgreens,” Graham has observed.

Relatively new to indoor farming

Having launched Greeny Grow in 2021, Graham is relatively new to indoor farming, but he has always had a connection to the world of agriculture. Graham left his family farm in Scotland in 1979 and traveled the world working with the biggest manufacturers of farm equipment. Through his efforts, farms in developing countries like Sudan had access to bailers and harvesters for the first time. In the early 1980s he went to work on an irrigation project in Saudi Arabia where they were harvesting enough Rhodes grass to satisfy the demand for camel feed in Dubai, Abu Dhabi, and Bahrain. I couldn’t believe what they could produce in rubbish soil that was mostly sand,” said Graham. “The plants were getting essential nutrients and water through an irrigation system.” This was the nascent system of hydroponics. Graham was getting a glimpse into the future of agriculture; he just didn’t realize he was destined to be part of it.

Fast forward a few decades and Graham and his wife, Pia, were running a successful business exporting timber from Sweden to Algeria. But when the supply chain became unreliable, the couple knew they needed “another leg for the business to stand on.”

The 2019 Urban Futures conference in Norway originally introduced Graham to the possibility of starting up an agribusiness with less traditional crops using cutting-edge techniques. He was originally inspired to grow algae for the cosmetic and pharmaceutical industry, but the timing wasn’t right.

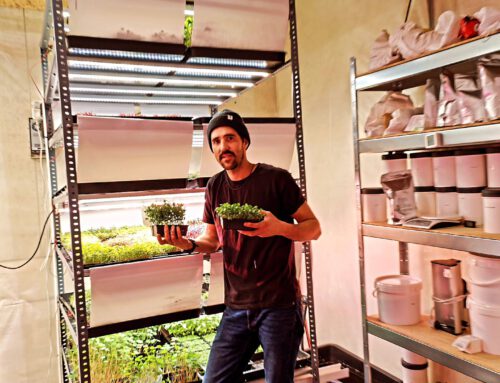

Using InstaGreen equipment for its simplicity & reliability

Once he decided to cultivate microgreens in an indoor vertical farm, he began scouring the internet for growing systems. “InstaGreen’s equipment appealed to me because of its simplicity. It works perfectly.” said Graham. Covid forced the group training to go online but Graham had an interesting weekend “Anneke and Remko were able to impart all the steps they’d gone through to get to where they were. This meant we could move forward easily without repeating mistakes they had made.”

Once he decided to cultivate microgreens in an indoor vertical farm, he began scouring the internet for growing systems. “InstaGreen’s equipment appealed to me because of its simplicity. It works perfectly.” said Graham. Covid forced the group training to go online but Graham had an interesting weekend “Anneke and Remko were able to impart all the steps they’d gone through to get to where they were. This meant we could move forward easily without repeating mistakes they had made.”

Graham yields about 800 boxes of microgreens a month from 6 units of InstaGreen’s system of stackable trays. In addition to supermarkets, Graham and his microgreens can be spotted at restaurants, farmstands and food trucks. Though InstaGreen’s original model is to offer living greens, Graham has adapted to his clients’ preferences by harvesting and packaging, the freshest most pristine greens possible in food-safe containers. While the lights and water are on timers and low-tech simplicity of the growing system ensures a reliability that requires little to no maintenance, there still are chores to do. Graham confesses that removing husks from sunflower packages is his least favorite task. “I hate sunflowers!” He laughs.

Fostering the health of the planet

Out on deliveries he meets people who want to know more about how Graham produces the vibrant and flavorful microgreens. How is it possible to cultivate radishes in just 10 days with little water and no soil? The curious are invited to tour his farm, a reclaimed industrial space down the road from where he lives. With 110 meters of growing space, about half of it is used for a variety of microgreens and the rest is used for another popular product, live lettuce heads.

Graham shares InstaGreen’s mission to foster the health of the planet. He would like to see a stop to harmful practices that are a routine part of traditional farming. Graham explains that in many northern climates Roundup is called “liquid sunshine.” “Since cereal crops don’t ripen, Roundup is applied to kill the crop, and it’s harvested when it dries up. He feels an urgency to undo some of the damage. “We need to leave a reasonable future for our children and grandchildren.”

Graham concedes that indoor vertical farming is not the only solution to our broken food system, but it does have clear advantages. Substituting soil for cellulose or coco fiber means that there are no soil borne pathogens. Water is used sparingly and there are no weeds to battle with toxic chemicals. Aside from a few controllable fruit flies and one tiny bird that once sneaked through the ventilation system, Greeny Grow doesn’t have to contend with pests.

Greeny Grow is a growing business

With produce quickly selling out, Graham wants to scale up the business and increase his sales territory from a 40-kilometer radius to 100 kilometers. “We are currently shaking the trees for investors.” He’ll need more space, more equipment, funds to cover utilities, more seeds and most certainly more staff. Will a kilt become the official uniform of Greeny Grow? “With our indoor temperature fixed at 20 degrees 365 days a year, you can wear anything you want, or nothing at all!” Graham jokes.

Greeny Grow’s early success is due in part to Graham’s tireless outreach efforts and eagerness to educate the public. Now that the charismatic Graham has given his community an appetite for delicious, nutritional food produced locally in a sustainable way, people are hungry for more.

We wish him all the best in his efforts to bring microgreens to more dinner tables in his growing market of Sweden!

Download InstaGreen_Greetings_From_Sweden.pdf

Article by Mary D’Apice